滚塑工艺

滚塑的发展

DEVELOPMENT OF ROTOMOULDING

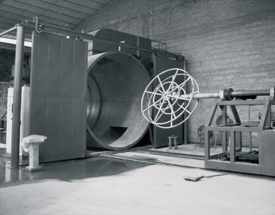

滚塑是一种成型中空塑料制品的工艺方法,也称旋转成型或旋转模型。将塑料粉末加入模具中,然后加热模具并使之沿两相互垂直的轴连接旋转,模具内树脂在重力和热量的作用下逐渐均匀地涂面、熔融黏附于模具内表面上,形成所需要的形状。然后冷却模具,脱模得到制品。滚塑工艺相对于塑料成型经常采用的挤出、注塑和吹塑等工艺而言,具有设备和模具投资少、适合于大中型或形状复杂塑料制品的生产、产品几乎无内应力等优点。

Rotomoulding is the technique for producing hollow plastic products.The first step is to put plastic powder into molders,then heat the molder to make the powder revolve around two vertical axes.The resin within the molder starts to pave the surface evenly due to the weight and heat followed by meltingon the inner surfface of molder.the second step is to cool down the molders and remove from the molder to get the products. Compared with what the plastic forming always take such as extrusion,injection,and blowing,the rotomoulding enjoys the advantage of small investment,excellent application for medium-and-super sized plastic products in complicated structures,and no stress,etc.

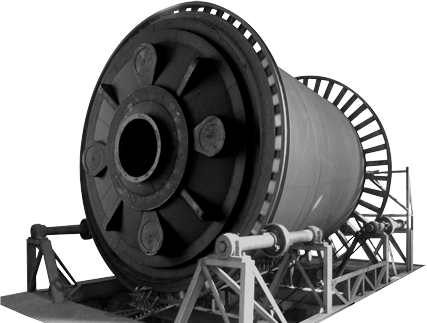

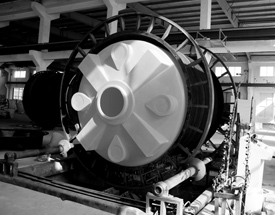

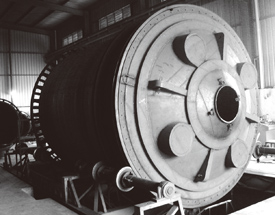

滚塑模具

ROTATIONAL MOLDING

滚塑原料

RAW MATERIALS OF ROTOMOULDING

线性低密度聚乙烯(LLDPE)是最理想的滚塑原料。LLDPE 是乙烯与丁烯、乙烯等的共聚物,分子呈线型结构,密度为0.93g/cm3。LLDPE用于滚塑的优点在于流动性好、热稳定性好、耐环境应力开裂性好、抗冲击性能好、刚性好。

LLDPE(Low Linear Density Polyethylene)is the ideal raw materials for rotomoulding.LLDPE is the copolymer of polythene,butylenes and so on with the linear molecule and the density of 0.93g/cm3.The advantage of LLDPE is it is better in liquidity,thermal stabilization and ESCR<impact, and hardness.

滚塑所采用的原料一般均为进口,我们采用乐天、美孚为主。除常用的颜色自己配色外,其余最好采用专门色料供应商的原料,如马来西亚 ICO及南京聚隆等,能调配耐强紫外线、抗强氧化性、甚至阻燃等专用料。

Rotational molding of raw materials used in general are imported, we use Le Tian, Mobil. Besides the common color your own color, the best use special pigment suppliers of raw materials, such as the Malaysia ICO and Nanjing Julong, special material blending resistant to ultraviolet, anti oxidation, and flame retardant.